Overview

This project was under a relatively tight scheduling window with rig up planned for February 17, 2021. When the FNL-1 debris sample arrived at the Coastal Chemical Co., LLC (CCC) Lab ( Jan 29, 2021) the N-SPEC 105 was already ordered, N-SPEC equipment was being mobilized and field personnel were being allocated for pre-job quarantine requirements.

Large Midstream Company Requires Chemical Cleaning Without Debris Sample

N-SPEC Pipeline Services, a Division of Coastal Chemical, was approached by a large midstream company to help develop a chemical cleaning protocol for a pipeline in British Columbia. The pipeline is 30-inch OD and 44.5 miles of very dry gas service. The client wanted to clean the pipeline in preparation for an EMAT (Electro-Magnetic Acoustic Transducer) tool run. EMAT tools provide very detailed information on pipeline internal conditions but they are sensitive and prone to sensor fouling from debris accumulation. Consequently, the client was keen on cleaning the pipeline as close to bare metal as possible. The client requested a preliminary cleaning proposal from N-SPEC, however the challenge for N-SPEC was there were no internal debris samples available for solids identification and chemical product testing.

Without the benefit of a pipeline sample, the N‑SPEC Project Management team referenced years of successful pipeline cleaning projects to generate a chemical procedure of four cleaning runs utilizing the N‑SPEC 105 pipeline cleaner mixed with diesel.

The procedure called for a 7,000gls of N-SPEC 105 chemical and diesel appropriate for cleaning the entirety of the length of the pipeline over 4 (1,750gls per) chemical cleaning runs. The chemical and diesel was to be injected at the pig launcher site and captured at the pig receiver site. This procedure was approved by the client and the paperwork for importing the products from the US to Canada began.

Based on the sensitivity of the EMAT tool and the need to make certain the pipeline was prepared after the cleaning phase, the client contracted with Pipepipelines2Data to assess the amount and location of the debris in the pipeline. A P2D tool run on the pipeline was performed Jan 20, the pipeline was mapped, the debris was measured and located in the pipeline. The P2D pig run also generated a solids sample from the pig receiver. A P2D technician arranged for the sample to be sent to the CCC Lab in Broussard, LA for analysis.

This project was under a relatively tight scheduling window with rig up planned for February 17, 2021. When the pipeline debris sample arrived at the CCC Lab (Jan 29, 2021) the N-SPEC 105 was already ordered, N-SPEC equipment was being mobilized and field personnel were being allocated for pre-job quarantine requirements.

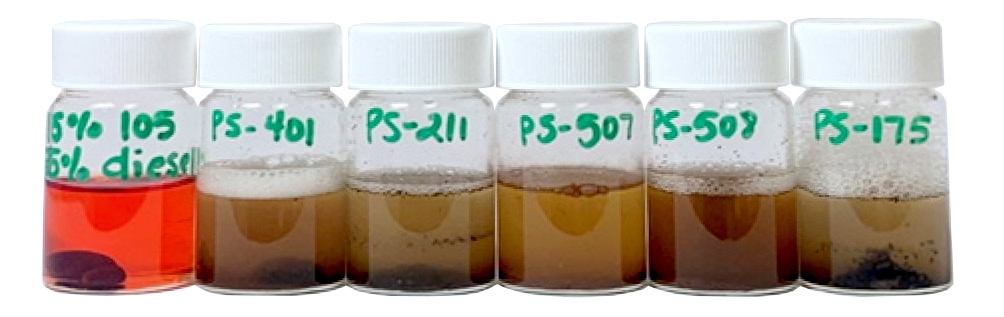

CCC Lab received the sample on a Friday morning and had four lab tests (XRD, XRF, Quantitative Solids, FTIR) and an N-SPEC Product Solvency Test completed for Monday morning review.

Testing Results

| PRODUCT | RESULT |

|---|---|

| 15% N-SPEC-105 / 85% Diesel | Non-soluble, Non-dispersible |

| PowderSolv 401 | Moderately soluble, Moderately dispersible |

| PowderSolv 211 | Moderately soluble, Moderately dispersible |

| PowderSolv 507 | Moderately soluble, Highly dispersible |

| PowderSolv 508 | Highly soluble, Highly dispersible |

| PowderSolv 175 | Moderately soluble, Moderately dispersible |

The XRD/XRF/FTIR lab tests results were typical for a dry gas pipeline in the region, but the product solvency test had an eye-opening result. The debris from the pipeline was completely insoluble in N-SPEC 105 and diesel (hydrocarbon based) but soluble in the CCC PowderSolv product pipeline (water based). Most likely the debris was water wet spent glycol from upstream dehydration operations that had been spilled into the pipeline during vessel upsets.

Immediately N-SPEC Project Management recognized from the product solvency test that the original cleaning chemical recommendation would not be as effective as necessary to prepare the pipeline for an EMAT run because the debris in the pipeline had zero affinity for the original cleaning chemical (N-SPEC 105) and its chosen diluent (diesel).

PS-211, PS-507, PS-508, PS-175 were eliminated from consideration because of the nature of the dry gas pipeline and dewpoint control concerns on the pipeline.

N-SPEC PMs agreed that PowderSolv 401 was the correct choice for this project. PowderSolv 401 is a patented, water based, neutral pH Iron Sulfide dissolver that is blended with a surfactant (for pipeline cleaning) and Ethylene Glycol. The PS-401 reaction with Iron compounds in the pipeline is a neutral reaction, that does not create H2S or any other hazardous by-products.

The ethylene glycol in PS-401 is blended with the water-based materials two provide two functions:

- control the dew point issues that putting a water-based product in a dry gas pipeline may create

- prevent the PS-401 cleaning product from freezing or dehydrating in the dry gas pipeline environment

Discussing Solutions

N-SPEC PMs requested a last-minute meeting with representatives from the client and P2D to discuss the lab testing results and the necessary product recommendation pivot from N-SPEC 105 and diesel to PowderSolv 401. This meeting was scheduled for February 3 – 17 days before the project was set to commence.

The February 3 meeting was held, the client was very receptive to the fit for purpose concept of changing the chemical cleaning procedure and the reasoning and data behind the changes.

There were a few concerns expressed by the client in the meeting.

- Would PS-401 cause any dew point issues? No, the glycol blended into the product would take care of that

- Would PS-401 cause any hydrates? No, the glycol would prevent that from happening

- Would PS-401 cause any corrosion problems in the pipeline? No, the product is pH neutral

- Would the PS-401 have any adverse reactions with system materials like seals, etc? None

- Would N-SPEC add Inhibited Methanol to the PS-401 to add fluid volume to the cleaning runs, and add additional security to prevent any dew point issues and freezing issues? Yes, CCC agreed to a 50:50 ratio of PowderSolv 401 to Methanol

- Would there be any issues with a water-based product on the job site with sub-zero temps? PS-401 has a -40F freeze point, -80F when mixed 1:1 with methanol

During the discussion of changing the chemical, it was also brought up that P2D’s debris mapping showed the overwhelming majority of the debris in the pipeline was over the last seven miles of the run. The client asked would

N-SPEC consider injecting the PS-401 just upstream of the beginning of the debris field to maximize the PS-401’s cleaning impact on the worst part of the pipeline? N-SPEC PMs agreed and adjusted the PS-401 injection point from the inlet of the pipeline at the pig launcher to a valve on a riser approximately 7.5 miles (at KM59) from the end of the run. This change also cut the volume recommended of PS-401 by 2200gls, saving the client a significant amount of money in the process.

The new proposal was approved by the client on February 4, the chemical order and field procedures were changed that day.

The PS-401 was delivered to the job site on February 15 and rig-up commenced on February 16.

Feb 19 – PS-401 injected in front of pig at KM 59 (1100 Gallons).

Feb 20 – Chemical injected in front of pig – 1100 gallons.

10% solids from fluid sample at separator.

Feb 21 – Chemical injected in front of pig – 1100 gallons.

25% solids from fluid sample at separator

Feb 22 – Chemical injected in front of pig 4 – 1532 gallons.

3% solids from fluid sample at separator

Feb 23 – Equipment rig down, demobilize

Brenntag Canada was instrumental in managing and performing this project for the client. BCAN facilitated all of the import paperwork and the delivery of the pipeline cleaning chemicals to the jobsite. BCAN also managed the blending of PS-401 with inhibited methanol before the injection process.

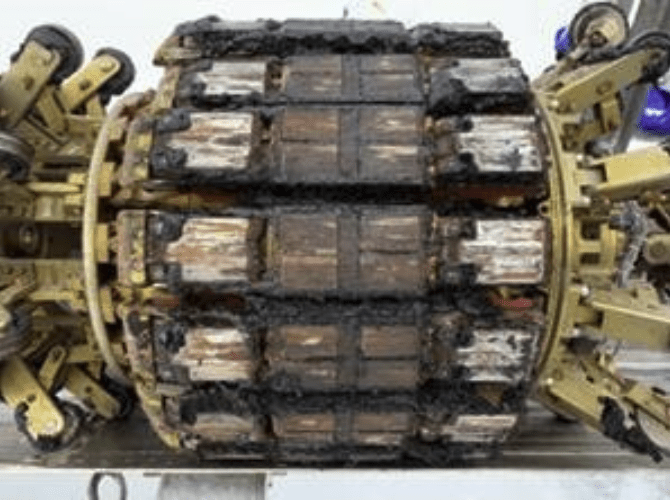

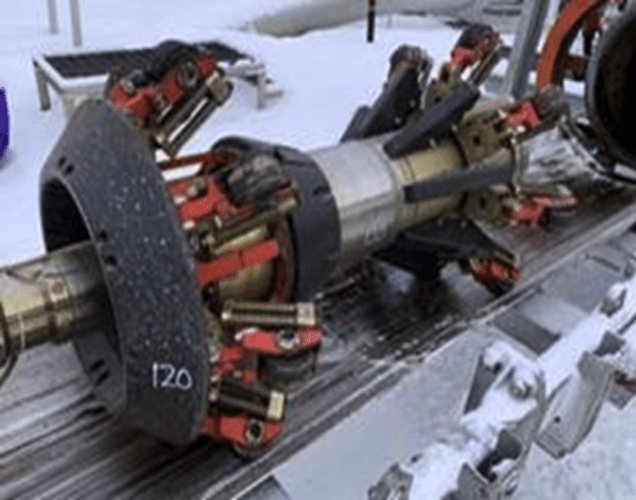

The client was very happy with the performance of the PowderSolv 401. There were no operational issues concerning water-based product in the pipeline and the pipeline was returned to normal service very quickly. Based on the cleanliness of the pipeline tools on the post cleaning runs and the clean pink chemical foam present, we can say the pipeline was clean and prepared for the EMAT. As a final proof, the client ran the P2D tool again with the following results:

The pipe wall debris map from KP59 (chemical injection location) to the end of the pipeline section – receiver infers that the chemical/mechanical cleaning campaign was effective as we can see significant improvements in specific locations as identified in the data captured in run 1 as hard debris.

The EMAT tool was successfully run on March 20, 2021