LEADING

WITH CHEMISTRY

COMMUNICATION AND TRAINING

Are a key component in making this program work. Coastal Chemical has developed a communication process that insures timely corrective action.

This process gets the results from the lab and communicates the problems found to the drilling rig with recommendations for solutions.

OIL PROGRAM

AND SAMPLING

PROGRAM

Samples are collected each month by Coastal Chemical personnel from all engines and mud pumps on each rig and sent to a laboratory for detailed analysis. Extended drain intervals are then made possible based on oil analysis results each month. A determination is made for each unit based on sump capacity, engine make and model, and type of operation for each component. This allows continuous protection of the equipment while minimizing oil changes and unit downtime.

MONTHLY

MANAGEMENT

REPORT

PREVENTATIVE

MAINTENANCE

TRAINING

OIL PROGRAM

AND SAMPLING

PROGRAM

Samples are collected each month by Coastal Chemical personnel from all engines and mud pumps on each rig and sent to a laboratory for detailed analysis. Extended drain intervals are then made possible based on oil analysis results each month. A determination is made for each unit based on sump capacity, engine make and model, and type of operation for each component. This allows continuous protection of the equipment while minimizing oil changes and unit downtime.

MONTHLY

MANAGEMENT

REPORT

PREVENTATIVE

MAINTENANCE

TRAINING

PRODUCT LINE INCLUDES

Coolants/

Antifreezes

Gasoline &

Diesel Fuels

Fuel Additives

Engine Oils

Heavy Duty

Motor Oils

Industrial

Lubricants

Synthetic

Lubricants

Greases

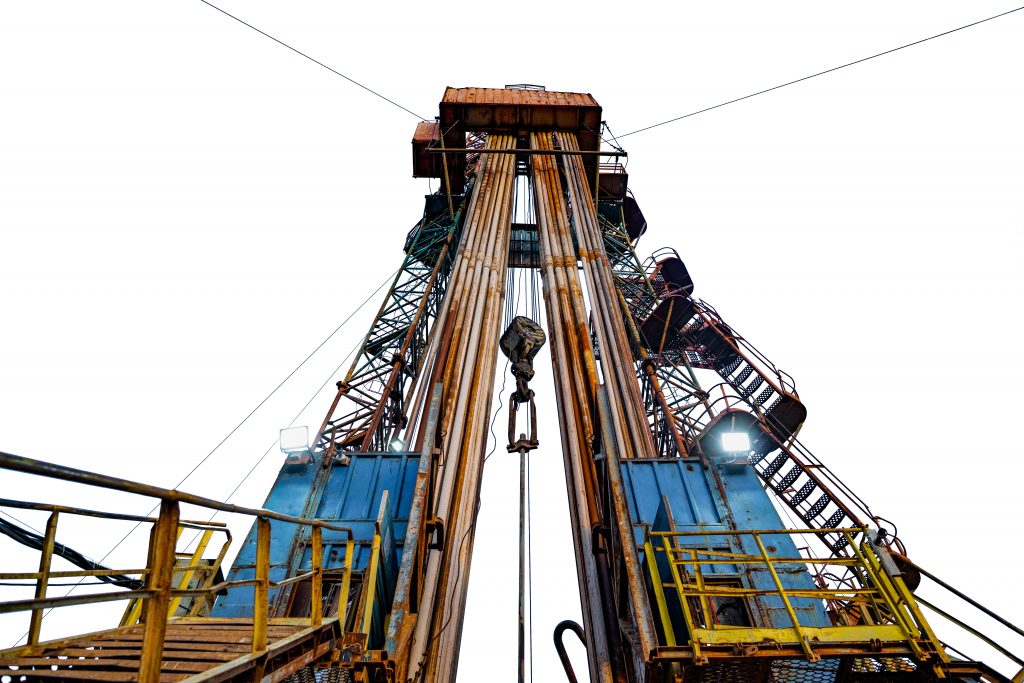

LEADING WITH CHEMISTRY IN DRILLING

Contact Coastal Chemical to learn how we help the drilling industry.